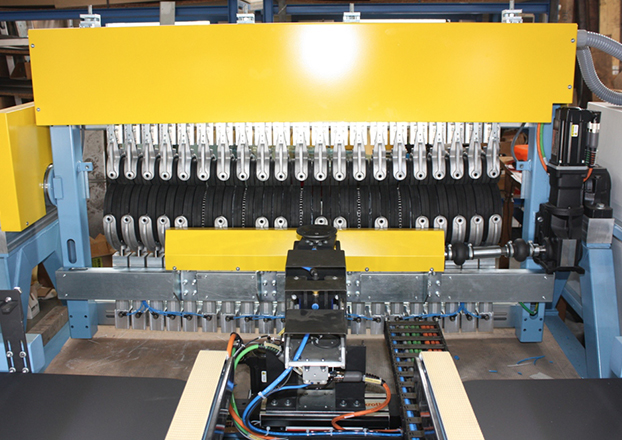

De-Airing

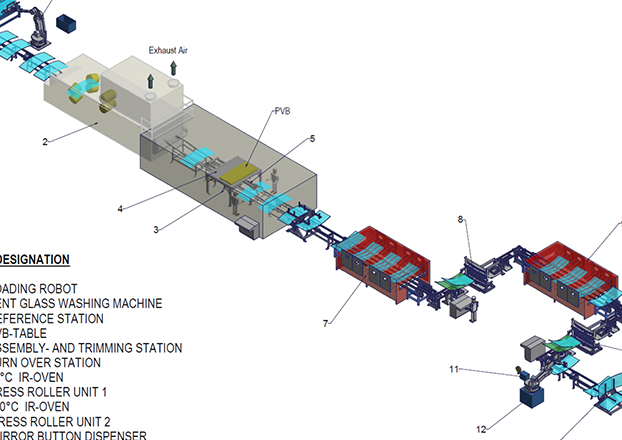

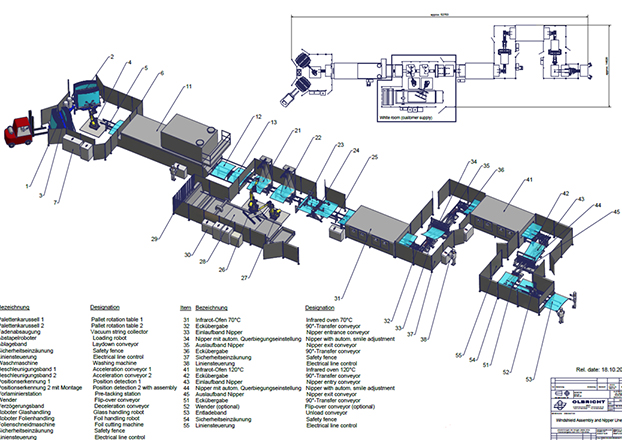

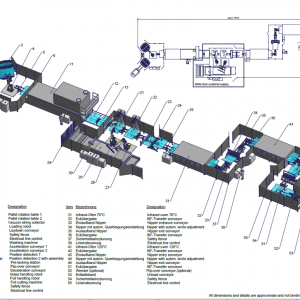

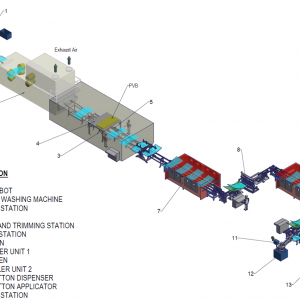

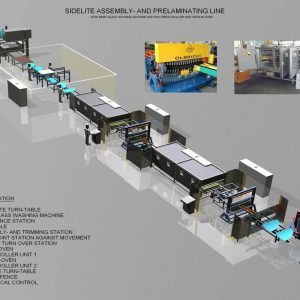

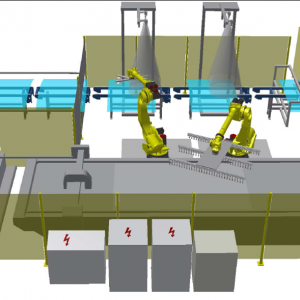

Turnkey Automotive Lamination Lines

- Assembly lines for windshield, sidelites and roof lites

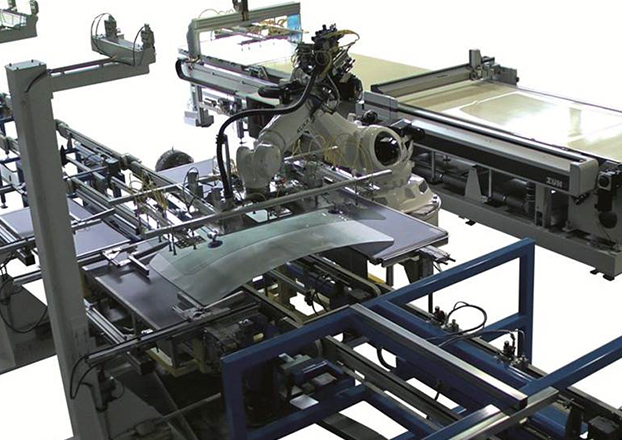

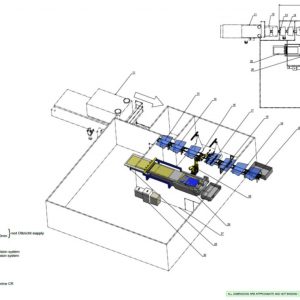

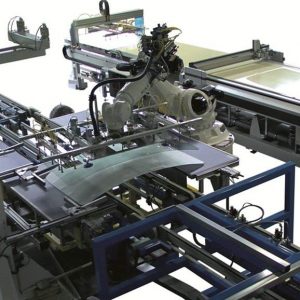

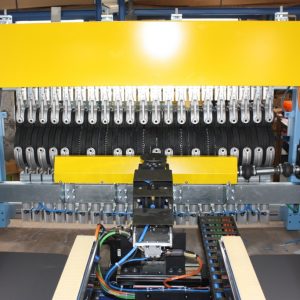

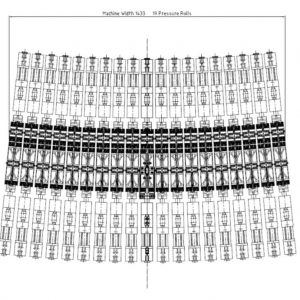

- Optimal solutions de-airing and tacking (pre-lamination)

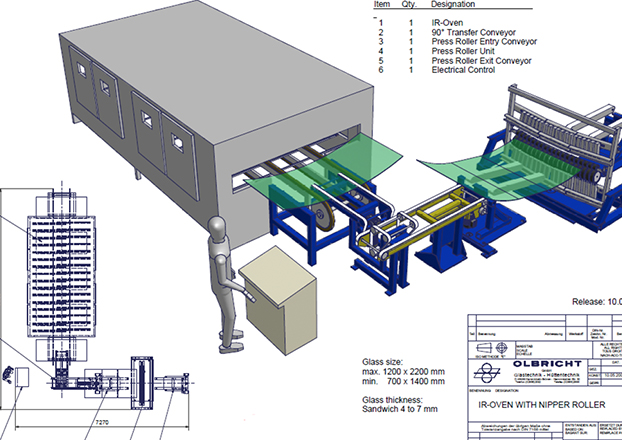

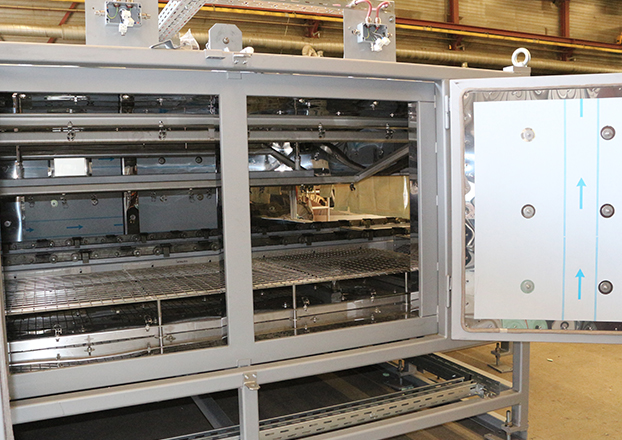

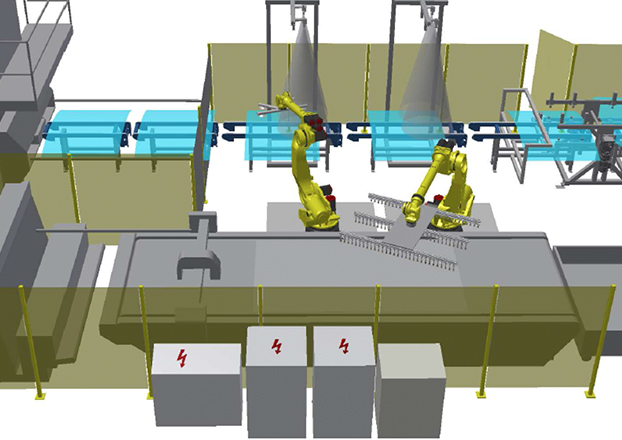

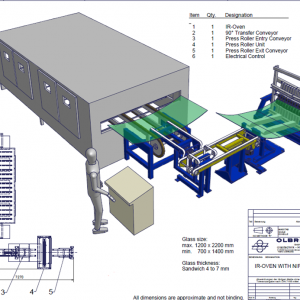

- Fully automated, high speed, low energy consumption IR oven & nipper roller lines

- Vacuum bag lines for windshields with connectors

- Optionally vacuum ring removal automation

- Automatic mirror button and bracket installation

- High production capacity up to 300 parts per hour

- On the fly change over (also for cross curvature of WS)

- Low energy & maintenance costs

- Fully automated operation

- Wide range of products (sidelite, sunroofs, windshields, min. 390 x 350 mm, max. 2.000 x 1.400 mm are possible)

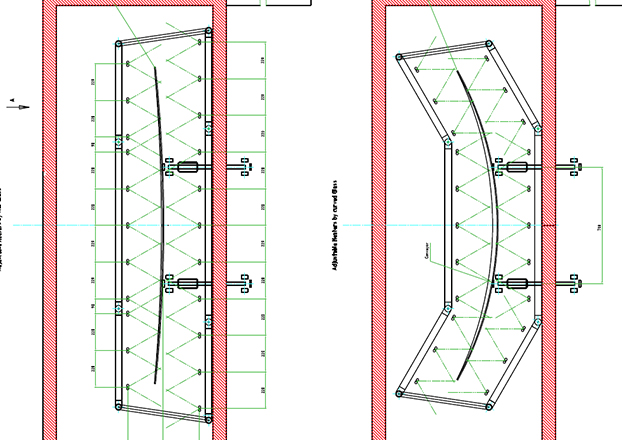

WindShields

- Horizontal sag / depth of bend: 0 – 300 mm

- Vertical sag / depth of bend: 30 mm

- Working width: 400 mm

Sidelites:

- Horizontal sag / depth of bend: 0 – 15 mm

- Vertical sag / depth of bend: 45 mm

- Working width: 300 mm

Semi-manual options for high bend radius WS (buses, trucks, etc.)

- A high quality machine with minimal maintenance costs

- Very low operational costs

- Low energy consumption

- Best in class product quality

- Very short ROIC